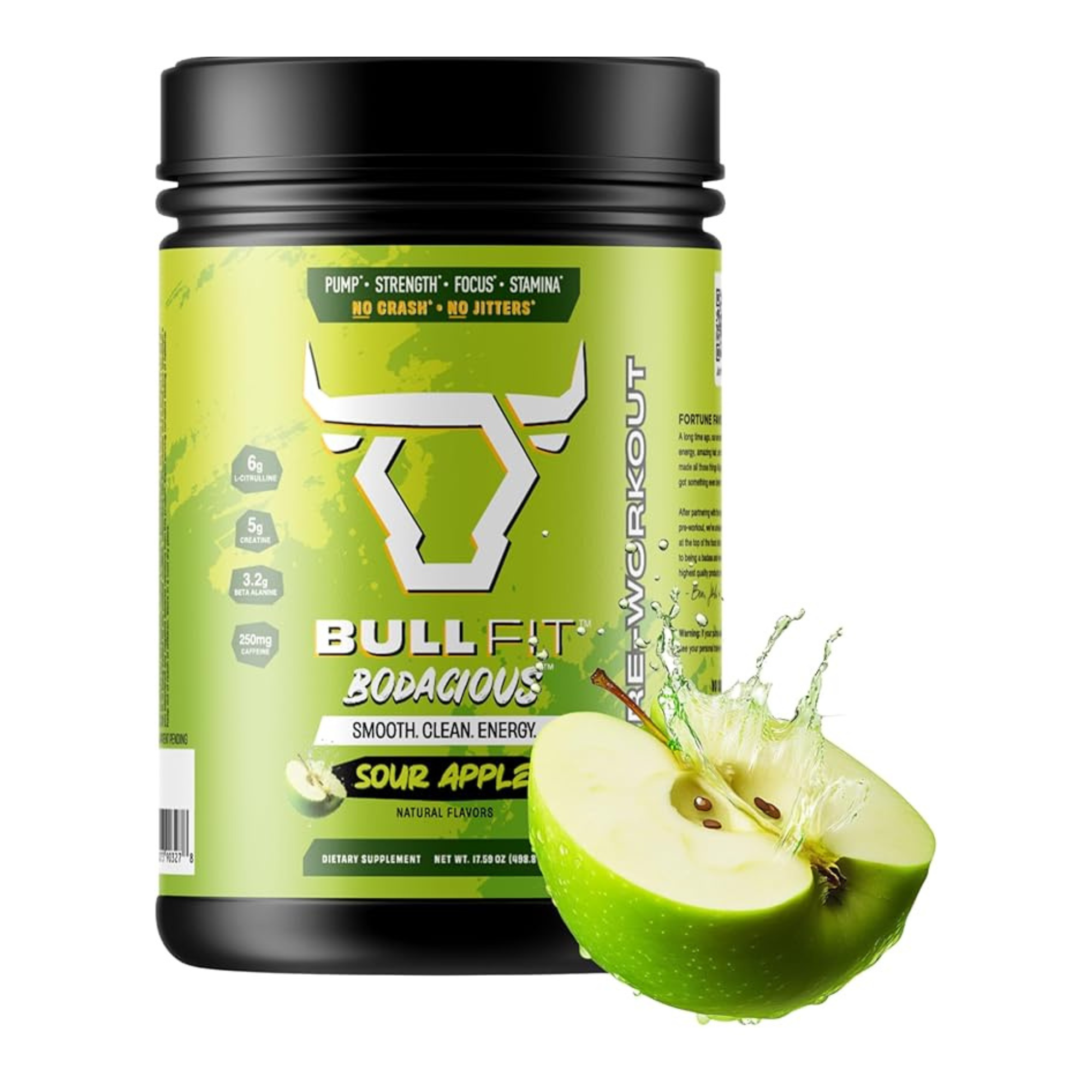

NO BULLSH*T. JUST BULLFIT.™

We're leading the charge in quality.

We meticulously craft our products without any compromises, ensuring they are free from artificial ingredients.

Manufacturing the correct way

At BullFit, every scoop starts with carefully sourced ingredients that are vetted for purity before they ever make it into our formulas. Nothing passes through without being sent to a third-party lab for verification — and we don’t settle for anything less than 97% pure.

Once approved, ingredients are blended in sterile, FDA-registered facilities where precision matters. Each batch is then tested again to guarantee consistency, so what’s on the label is exactly what’s in your scoop. No filler. No shortcuts. Just clean, clinically dosed supplements built the right way.

Our process takes longer, but that’s the point. From raw ingredient sourcing to the final seal on every tub, we obsess over quality so you never have to second-guess what’s fueling your body. This is the BullFit standard — tested, trusted, and made to perform.

Pharmacist-Formulated

At BullFit, every formula starts with Todd, our PharmD, who brings a clinical eye to every ingredient. Each product is pharmacist-formulated and clinically dosed, meaning you get the exact amounts proven to actually work — not the under-dosed blends you’ll find elsewhere. We keep things clean, effective, and backed by science so you can feel the difference in every scoop.

Sourcing the Best Ingredients

BullFit places immense value on the origins of our ingredients. We collaborate with reliable suppliers who align with our commitment to quality, science, and responsibility. By prioritizing ingredient quality, we ensure our products are formulated for optimal potency, absorption, and digestibility, because we believe that superior ingredients lead to superior products.

FOUR ROUNDS OF TESTING

TEST 1: Every single raw ingredient and material is tested by our manufacturing team when it arrives. We screen for contaminants in all raw materials.

TEST 2: We test to ensure the correct amount of ingredients are used in every formulation. We diligently check every bottle, label or stick pack for defects individually.

TEST 3: Before being approved for sale, finished products are tested to confirm the identity, potency and purity of the products, and to confirm that no microbiological contamination occurred during manufacturing.

TEST 4: We test the stability of each product to ensure that each product will meet the claims listed on the label up to the expiration date